When you looking for milling for home machinists, you must consider not only the quality but also price and customer reviews. But among hundreds of product with different price range, choosing suitable milling for home machinists is not an easy task. In this post, we show you how to find the right milling for home machinists along with our top-rated reviews. Please check out our suggestions to find the best milling for home machinists for you.

Best milling for home machinists

Related posts:

Best milling for home machinists reviews

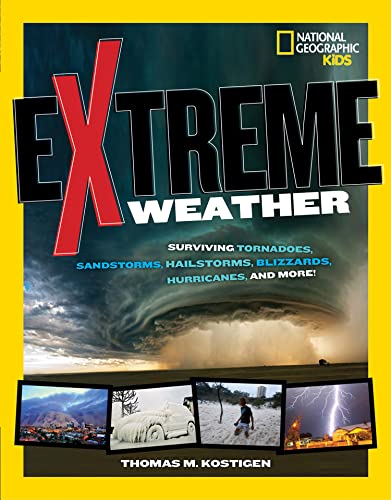

1. Milling for Home Machinists

Feature

Used Book in Good ConditionDescription

Four minor and four major milling projects are provided that provide the opportunity to gain basic skills, and then use that expertise to build a series of useful and increasingly complex tools.2. Milling Machine for Home Machinists, The

Description

This book provides the detailed knowledge you need to successfully choose, install, and operate a milling machine in your home workshop. Lavishly illustrated with color photographs and diagrams, it will help you to understand which accessories are essential, and which can be postponed until your activity demands it. The usage of each machine and accessory is explained in detail for the vast majority of applications in an active shop.3. Metalworker's Data Book for Home Machinists: The Essential Reference Guide for Everyone Who Works with Metal

Description

This comprehensive data book offers a wide range of reliable information, useful in both the metalworking workshop and for those designing engineered items, tools, and machines. In one concise volume, it provides data that are otherwise available only by reference to many different sources or more expensive publications. From drill sizes, turning tools, and thread data to screw cutting combinations, electrical components, and hardware dimensions, Metalworker's Data Book for Home Machinists covers 31 categories of essential data that will assist the metalworker both at the design stage of a project and during its manufacture in the workshop. A valuable resource for machinists working to current standards, it includes details of the latest metric thread forms. And for those involved in restoration work, the book also offers details related to systems that are no longer widely used and for which data is not easy to locate.4. Home Machinists Handbook

Description

Here's everything the do-it-yourselfer needs to set up, and operate a handy-man's machine shop. Areas covered range from shop requirements and proper lighting to buying, using, and storing tools.5. Milling: A Complete Course (Workshop Practice)

Feature

CHRIS LLOYD SALESDescription

A complete self-tuition course which assumes no previous experience of using the milling machine; through the medium of four minor and four magor projects, it leads prospective users of the milling machine through all of the techniques involved.6. Gears and Gear Cutting for Home Machinists (Fox Chapel Publishing) Practical, Hands-On Guide to Designing and Cutting Gears Inexpensively on a Lathe or Milling Machine; Simple, Non-Technical Language

Description

This practical, hands-on guide will assist anyone who wants to cut gears inexpensively on a lathe or milling machine.

- Learn the fundamentals needed to design your own gears and gear trains

- Understand the complexity of gears and how to machine them, in a very clearly presented and easy to understand way

- Plain, simple and non-technical language, with the mathematics kept to the simplest form

- Information on tooth forms & sizes, rack & pinion gears, bevel wheels, making gear cutters, and more

- Well-illustrated with concise technical diagrams and B&W photos

Gears in one form or another are a part of most mechanisms, but they are by no means as simple as they appear!

Gears & Gear Cutting for Home Machinists is a practical, hands-on guide for anyone who wants to cut gears inexpensively on a lathe or milling machine. This book teaches the fundamentals needed to design gears and gear trains using plain, simple, non-technical language that keeps the level of mathematics down to its simplest form. It covers all the questions raised by enthusiasts who have watched the author demonstrating gear-cutting techniques at exhibitions throughout Britain, where his advice on engineering matters is constantly sought.

With information on tooth forms & sizes, rack & pinion gears, bevel wheels, making gear cutters, and more, Gears & Gear Cutting for Home Machinists is well illustrated with concise technical diagrams and photographs.

7. Metalworker's Workshop for Home Machinists, The

Description

This informative book covers all aspects of setting up a fully equipped metalworking workshop. It will benefit anyone who is building a workshop for the first time, or just wants to upgrade an existing operation. If you have had your lathe stuck in a corner of the garage for years, this is definitely the book for you. Even if you think your workshop is already complete, you'll discover eye-opening new information here.8. Basic Lathework for Home Machinists (Fox Chapel Publishing) Essential Handbook to the Lathe with Hundreds of Photos & Diagrams and Expert Tips & Advice; Learn to Use Your Lathe to Its Full Potential

Feature

Used Book in Good ConditionDescription

Expand your enjoyment of the versatile lathe and take full advantage of its extensive capabilities!

- Essential handbook to the lathe covering everything from the selection of a machine and its construction to tooling and machining operations

- Hundreds of photos and diagrams help take the mystery out of your lathe

- In-depth introduction to the modern lathe, including a thorough review of its layout and components, and what to consider when buying a new or used machine

- Useful advice on steadies, tool height, and setting up

- Expert tips on how to use cutting fluids and mandrels, plus how to complete a parting off operation with confidence

Most home lathes are probably never used to their full potential. Perfect for any home machinist with a new lathe, this comprehensive guide is designed to expand your enjoyment of this versatile machine and take full advantage of its extensive capabilities. Profusely illustrated with hundreds of clear photographs and concise diagrams, it provides in-depth coverage of tooling and machining operations.

This book deals with all aspects of the lathe covering the selection of a machine and its construction, including modern types of machines as well as the more traditional models. All aspects of tooling, both traditional and modern are covered in depth, as are all machining operations, including general machining, taper turning, threading and boring.

Inside you'll find a thorough review of basic layout and components, plus the three things you need to consider when buying a new or used machine. Learn to select common cutting tools, and discover the key features of work-holding devices like chucks, tool posts, and faceplates.

Basic Lathework for Home Machinists covers all the most important rules and practices for safe general machining operations. Get handy advice on steadies, tool height, and setting up, plus expert tips on how to use cutting fluids and mandrels. Find out how to complete a parting off operation with confidence, and successfully accomplish threading, boring, taper turning, and many other tasks.

Author Stan Bray also pays particular attention to modern applications such as the conversion of power supplies from single to three phase and the use of digital equipment to improve efficiency.

Basic Lathework for Home Machinists is suitable for use by beginners with no knowledge at all of lathe work, as well as those who are more advanced and want to improve their skills.

"Basic Lathework is the perfect book for any home machinist with a new lathe. For such a broad subject, the author has effectively managed to cover all the need-to-know areas and this book is all that's required to take the mystery out of that new machine in your shop."

George Bulliss,

The Home Shop Machinist magazine

9. Mini-Lathe Tools and Projects for Home Machinists (Fox Chapel Publishing) Simple, Practical Designs & Modifications to Extend & Improve the Versatility of Your Small Metal Lathe; Over 200 Photos

Description

Everyone who has a mini-lathe needs this book!

- Projects designed to extend and improve the versatility of the mini-lathe

- Guide to tricks and techniques that every mini-lathe operator needs to master

- Well illustrated with clear diagrams and crisp color photos

- Follow-on book to the author's Mini-Lathe for Home Machinists

The ubiquitous mini-lathe has provided an entry into the model engineering hobby for thousands. Available in a wide variety of styles and colors, from an equally varied assortment of vendors, the various models share the basic mini-lathe foundation, and readers will find David Fenner's projects and discussion helpful regardless of their lathe's provenance.

The simple and practical tools and modifications the author features will help the hobbyist get the most from this versatile little machine. The straightforward, easy-to-construct designs provide a great deal of flexibility; modifying to better suit your shop's needs or scaling to fit a different machine are easily accomplished.

Owners of mini-lathes and other similarly-sized machines will find Mini-Lathe Tools and Projects for Home Machinists to be a valuable resource for the workshop.

10. Milling Machine & Accessories: And Accessories Choosing and Using (Workshop Practice Series)